Built Different. Built to Last.

We don’t just manufacture transformers—we engineer power solutions that withstand the toughest industrial conditions while delivering consistent performance year after year.

Proven Reliability

Our transformers operate for decades with minimal maintenance, backed by rigorous testing that exceeds industry standards. When your operation can’t afford downtime, Acme delivers the dependability you need.

Custom Engineering

Every transformer is built to your exact specifications and site requirements. Our engineers work directly with your team to ensure optimal performance for your unique electrical demands.

Rapid Response Service

Factory-trained technicians provide 24/7 support with genuine parts inventory maintained locally. We understand that transformer issues need immediate attention, not next-week solutions.

Stay Connected

Get the latest updates, technical insights, and industry news delivered directly to the inbox.

Powering Progress Since Day One

For over three decades, Acme Electric has been the go-to name when power reliability can’t be compromised. We design and manufacture transformers that keep everything from manufacturing plants to data centers running smoothly, because we know that when the lights go out, everything else stops too. Our team of engineers doesn’t just build equipment—they solve the complex power challenges that keep business owners up at night. Started in a small workshop by two electrical engineers who were tired of seeing good businesses fail due to power problems, we’ve grown into a trusted partner for companies who need their electrical systems to work perfectly, every single time.

The breakthrough came in 1998 when we developed our first custom transformer for a local textile mill that had been struggling with voltage fluctuations for months. Word spread quickly through the industrial community, and soon we were fielding calls from facilities managers across the region who had heard about “those transformer guys who actually fix problems.” What started as weekend projects in a garage became the foundation for innovations that now power some of the most demanding operations in North America.

Gear for Every Type of Explorer

From lightweight options for quick getaways to rugged designs for extended journeys, each model is made to match different needs and environments.

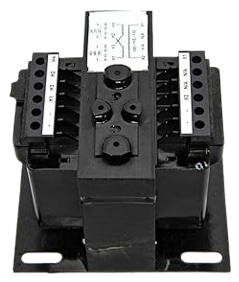

Industrial Control Transformers

General Purpose Transformers

Encapsulated (Epoxy) Transformers

Buck-Boost Transformers

Tools Designed for the Demands of the Outdoors

From heavy-duty industrial applications to emergency backup solutions, our transformers deliver the reliable performance your operations depend on. Built tough, tested harder, and engineered to keep your business running no matter what.

Buck-Boost 0.50 kVA, 120x240V to 12/24V, Steel

Power Unit 2 kVA, 120/240V Input, Wall Mount

Buck-Boost 0.75 kVA, 120x240V to 16/32V, 60Hz

Dry-Type 0.75 kVA, 240x480V, 4-Winding, Wall Steel

Open Core 0.5 kVA, 240/480V to 120V, Industrial

Three-Phase 75 kVA, 480D to 240D/120V, Distribution

Got Questions?

This section covers the most common questions customers ask about these electrical components.

Most units are designed to operate reliably for 20-30 years with proper maintenance. Lifespan depends on operating conditions, load factors, and regular inspections. Units in harsh environments may require more frequent servicing.

Sizing depends on the total load requirements, voltage specifications, and future expansion plans. An electrical engineer should calculate the exact requirements based on connected equipment and safety margins.

Many models are rated for outdoor installation with appropriate weatherproof enclosures. Indoor units require different housing specifications. The installation environment determines which type and protection rating is needed.

Annual inspections are recommended for most installations. This includes checking connections, testing insulation, and monitoring oil levels where applicable. High-use or critical applications may need more frequent attention.

Failure modes vary but often involve protective systems shutting down the unit safely. Most installations include backup systems or redundancy to maintain power during repairs. Professional diagnosis is required to determine repair versus replacement options.

Have a Question? Get the Information You Need

Real Results from Power Professionals

Trusted by engineers and facility managers who depend on reliable power distribution every single day.

Switched our entire campus to Acme transformers. The harmonics filtering on their industrial series cleaned up our power quality issues that three other brands couldn’t solve.

Marcus Chen

We run three shifts, 24/7. Our Acme transformers have been running for 3 years straight with zero downtime. The built-in monitoring saved us from a potential overload situation last month.

Jennifer Wu

I’ve installed probably 200+ transformers over my career. Acme’s mounting system cuts installation time by 30%, and their tech support actually picks up the phone when you need them.